torsion test experiment brass|torsional testing of shafts : exporter Experiment 1: System Identification. In practice, the system parameters of a piece of equipment, such as the inertia, spring constant, and damping ratios are often unknown. In this section of .

Resultado da 30 de dez. de 2023 · 158 Likes, TikTok video from Liam (@liamcortespodcast): “Greg Ferreira fala sobre a sua tatuagem na .

{plog:ftitle_list}

WEBllll Cupom de desconto Senac Frete Grátis: Ganhe até 50% de desconto para comerciários e seus dependentes alunos e exalunos dos cursos técnicos e ensino médio técnico do Senac São Paulo e egressos do ensino público + Parcela com desconto de até 50% para comerciários e seus dependentes, alunos e ex alunos dos cursos técnicos e .

In this experiment, solid cylindrical specimen of steel or brass will be subjected to a torsional load. The test will be conducted until failure (i. it will end in the . Torsion test have been perform on three different materials (brass, steel and aluminum) and with the help of experimental data, value of modulus of rigidity and shear .

The objective of this experiment was to test the circular cross-sectional specimens: steel and brass, to determine modulus of rigidity. Then comparing the experimental values and the published values together to determine if the . The experiment involves twisting steel and brass rods of different lengths using known torques and measuring the angular deflection. Graphs of the data are used to calculate G, finding values of 68.46 GPa for steel and 38.8 .ENGR 2332 Mechanics of Materials Lab No. 9 Torsion Test and Analysis Austin Ciervo March 29, 2018 Objectives The purpose of this experiment is to analyze the deformation of the circular shaft subjected to a torque. We will also learn .

Experiment 1: System Identification. In practice, the system parameters of a piece of equipment, such as the inertia, spring constant, and damping ratios are often unknown. In this section of .Assessment #2: Torsion test experiment (15 pts) A brass specimen has been subjected to forsion test, the torque (moment) versus angular deflection (0) is recorded for you in the table below. The specimen is 300 mm length with a 10 .

This video shows the Torsion Test experiment for brass and aluminum performed for AEM 251: Mechanics of Materials Lab performed in the Spring of 2021. The vi.

In this torsion testing experiment, the torsion test was evaluated as a system for calculating the torsional rigidity (GJ), modulus of rigidity (G), and the shear yield stress (τ) for aluminum, mild steel, and brass. Torsion testing of basic grade mild steel with an axial torsional testing equipment is one type of test used to assess the torsional characteristics of the structural material. Experiment No. Torsion Test of Metals and Polymers. . September 14, 2019 Objective. The purpose of the lab was to understand how torsion is applied and how to read data related to torsion based on using the .

Strain corresponding to specified torque in torsion test. It is equal to torsional deformation multiplied by the radius of the shaft. It's units are radians. 14. Torsional Stress, T: Shear stress developed in a material subjected to a .

EQUIPMENT & MATERIALS 3.1 Equipment Torsion Tester Machine 3.2 Materials Aluminum & Mild Steel ENT 251/4 – Solid Mechanics Laboratory Module 15 Fig. 1 Torsion test machine 3. TORSION TEST The most notable test that demonstrates the effects of shearing forces and resulting stresses is the torsion test of a solid circular bar or rod. As a .The three common forms that torsion testing take include failure, proof and operational. A torsion test for failure requires that the test sample be twisted until it breaks and is designed to measure the strength of the sample. A proof test is designed to observe the material under a specified torque load over a set period of time.Experiment Two- Torsional test Experiment Two (2) Torsional testing of Circular Shafts Introduction: Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating (such as drive shafts on engines, motors and turbines) or stationary (such as with a bolt or screw).ENGR 2332 Mechanics of Materials Lab No. 9 Torsion Test and Analysis Austin Ciervo March 29, 2018 Objectives The purpose of this experiment is to analyze the deformation of the circular shaft subjected to a torque. We will also learn the test method to obtain the shear modulus of elasticity for materials.

Volume 1. Yusuf Khan, in Encyclopedia of Biomedical Engineering, 2019. Torsion testing. Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and breaking angle of a material or the interface between two materials. Typically a longitudinal sample is placed in a .

Using the torsion testing machine, we will find out modulus of rigidity and shearing property of mild steel specimen. Main objective of torsion testing experiment is following, To find modulus of rigidity of test machine. To draw torque (T) Vs Angle of Twist (θ) Curve. To find Breaking Torque and shearing stress.This lab report summarizes an experiment to determine the shear modulus of mild steel samples under torsion. Cylindrical mild steel specimens were subjected to increasing torque loads, and the angle of twist was measured. By plotting torque versus angle of twist, the shear modulus could be calculated from the slope. The experiment aimed to find properties like shear stress, shear .Experiment No. 2 VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: It is similar in principle to Rockwell hardness test, but utilizes a different indentor and different magnitudes of loads.

TORSION TEST LAB REPORT - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document is a lab report for a torsion testing experiment conducted by a team of students. The experiment aimed to compare experimental and theoretical shear modulus values for different materials, and compare maximum torque ratios .

One of the most common examples of torsion in engineering design is the power generated by transmission shafts. We can quickly understand how twist generates power just by doing a simple dimensional analysis.Power is measured in the unit of Watts [W], and 1 W = 1 N m s-1.At the outset of this section, we noted that torque was a twisting couple, which means that it has .

I. Experimental Procedures In this experiment, students were to test the cross-sectional specimens: steel and brass, to determine the modulus of rigidity. Next, comparing the published values with the experimental values to determine if the modulus of rigidity gives correct outcomes. The specimens were measured and placed into the torsion testing apparatus . Torsion Test on Mild Steel | KTU S4 Material Testing Lab | Experiment Setup Introduction To put meaning to the data and conclusions drawn in this experiment several things must be known about the materials tested and the theory behind torsion testing. The two materials tested, cast iron and mild .

This torsion test experiment is carried out on rods made of mild steel which is a standard torsion application instrument with in diameter 0 and 0 in length. The rod is connected to a machine that measures torque at one end, and the other .Experiment Two- Torsional test Experiment Two (2) Torsional testing of Circular Shafts Introduction: Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating (such as drive shafts on engines, motors and turbines) or stationary (such as with a bolt or screw).Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. ii. Torsion Only: Applying only torsional loads to the test specimen iii. Failure Testing: Twisting the product, component, or specimen until failure. Failure can be classified as either a physical break or a kink/defect in the specimen.

Test Procedure. Part 1: Determination of Rigidity modulus using Torsion pendulum alone. The radius of the suspension wire is measured using a screw gauge. The length of the suspension wire is adjusted to suitable values. The wire for the test is tightened at its bottom to the disc and its top to the bracket. https://engineers.academy/Analysis of results from a torsion test demonstration on a sample of 0.4% carbon steel. From the torsion test results, we are able .Click here to see a close-up view of the first part of the experiment. . Finally, we can compute the shear modulus for the brass rod from our knowledge of its torsion constant and its dimensions. Given that: (5) where r is the radius, l is the length, and S is the shear modulus for the rod, you should compute the value of the shear modulus .

torsional testing of shafts

The torsion test is a mechanical test method used to examine the deformation of a specimen through a twisting/rotating motion.. Torsion, in its simplest form, is the action of twisting. Many everyday materials, components, component assemblies, and end-user products used in various industries are designed with the primary purpose of supporting this direction of movement.

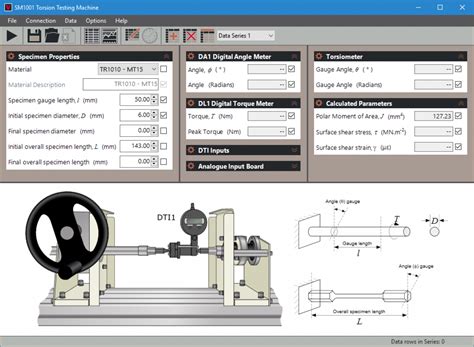

EXPERIMENT 2 TORSION TEST 1.0 Objective i. To determine the modulus of rigidity, maximum shearing stress, maximum shearing strain and Poisson`s ratio for the tested specimen. . Usually, the fracture will occur between 100 to 200 rotations and 200 to 300 rotations for the mild steel and brass material respectively and continued to specimen .This experiment is performed using The SM1001 30Nm Torsion Testing Machine shown in the figure below. Figure 2: SM1001 30Nm Torsion Testing Machine . Specimen Setup 1. Accurately measure and record the dimensions of your specimen. 2. Choose the correct sockets to fit your specimen . Microsoft Word - Torsion Test.docA torsion test machine along with angle of twist measuring attachment. 2. Standard specimen of mild steel. 3. Steel rule. 4. Vernnier caliper or a micrometer. Theory:- For transmitting power through a rotating shaft it is necessary to apply a turning force. The force is applied tangentially and in the plane of transverse cross section.

What is the purpose of the torsion experiment? The purpose of a torsional experiment is to see how different engineering materials respond when torque is applied to them. Torsion testing requires the twisting of a specimen along its primary axis and is a practical test for acquiring mechanical property data like torsional shear stress/strain .

vertical autoclave without drying

centrifuge g to rpm in china

Resultado da Gostosa sarinha caus. Timorga. FOLLOW. 2 22,2K. 60. 6. Gostosa sarinha caus pictures and videos on EroMe. The album about Gostosa sarinha .

torsion test experiment brass|torsional testing of shafts